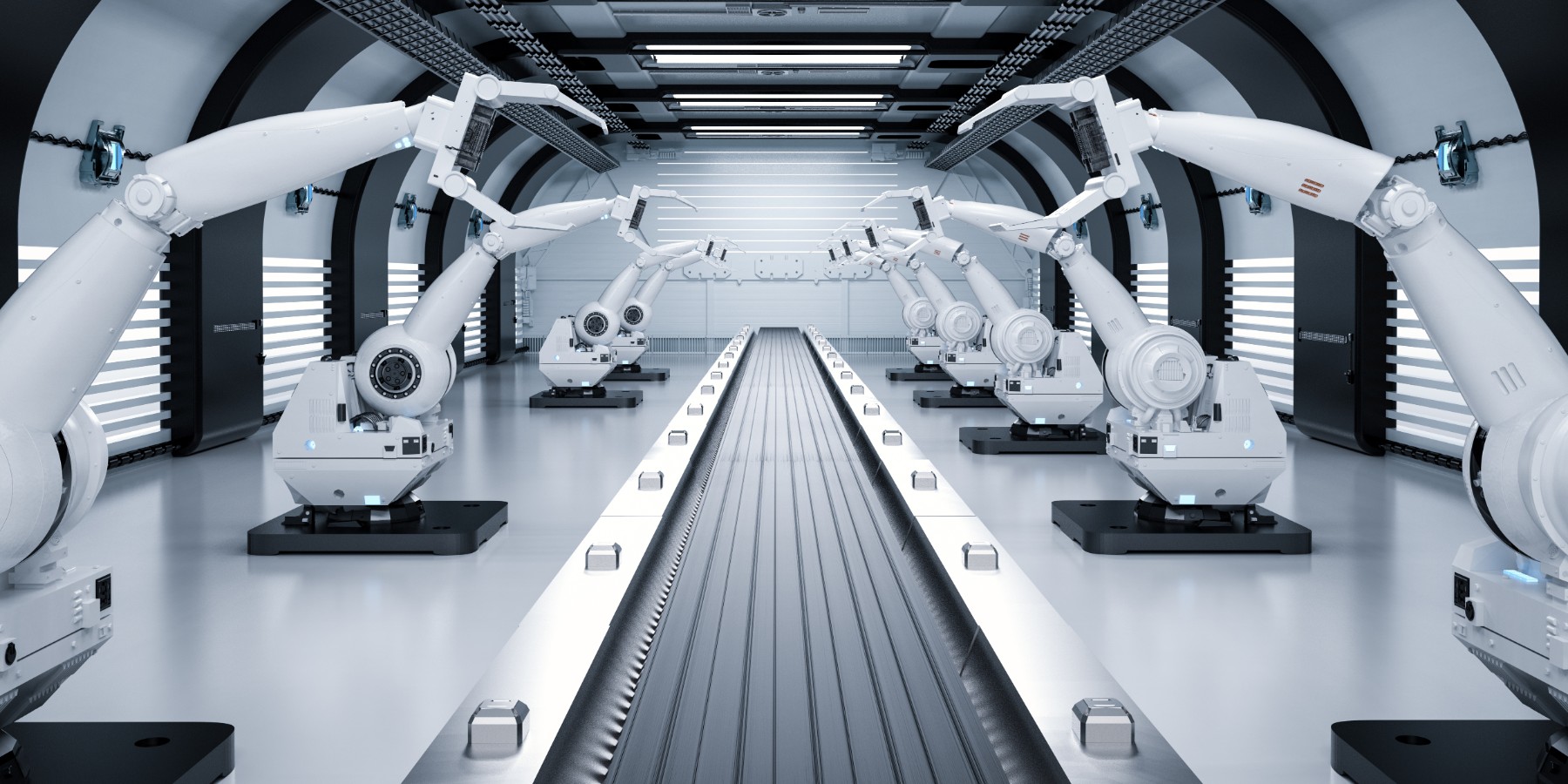

The drive to improve and enhance those supply chains means that this has long been an area rich in digitisation and technological innovation. Now, a combination of advanced robotics and the Internet of Things (IoT) is driving a new wave of enhancements.

From the production line outwards

Industrial and manufacturing organisations have, of course, harnessed robotics on the production line for many decades now. They were also early adopters of IoT technology in the same settings, quickly taking advantage of connected sensors’ abilities to achieve predictive maintenance of physical assets and drive more intelligent factory floors.

However, move from the production line out into the warehouse and beyond and there are still myriad opportunities for these business to derive benefits from both robotics and IoT deployments. Moreover, as demand for superfast delivery services goes up, coupled with the inexorable rise of ecommerce traffic, so businesses need to search for more and more ways to speed up and enhance their ability to get products to customers.

What does this look like in practice? At the simplest end of the spectrum, automated guided vehicles (AGVs) are rapidly being rolled out in supply chain warehouses, driven by IoT-enabled sensors and navigating the space far faster than any human worker. Coupled with robotics for picking items from throughout the warehouse, they offer a truly 24/7/365 means for businesses to speed up and streamline their warehouse functions – drastically reducing incidences of human error in the process.

Outside of the warehouse, similar technologies can enhance processes throughout the shipping and logistics chain. IoT-enabled sensors in vehicles can be part of smarter navigation systems, proactive approaches to vehicle maintenance and even strategies for ensuring better occupational health among drivers. Meanwhile, robotics can work in harmony with these vehicles to select the right items at the right place, and streamline the processes of dropping off or picking up components.